1. Basic Chemistry and Crystallographic Design of Boron Carbide

1.1 Molecular Composition and Architectural Complexity

(Boron Carbide Ceramic)

Boron carbide (B ₄ C) stands as one of one of the most fascinating and technologically essential ceramic materials as a result of its one-of-a-kind mix of extreme solidity, reduced density, and remarkable neutron absorption capability.

Chemically, it is a non-stoichiometric substance primarily made up of boron and carbon atoms, with an idealized formula of B ₄ C, though its real make-up can vary from B FOUR C to B ₁₀. ₅ C, reflecting a large homogeneity array controlled by the substitution mechanisms within its facility crystal lattice.

The crystal framework of boron carbide belongs to the rhombohedral system (area group R3̄m), identified by a three-dimensional network of 12-atom icosahedra– collections of boron atoms– linked by direct C-B-C or C-C chains along the trigonal axis.

These icosahedra, each containing 11 boron atoms and 1 carbon atom (B ₁₁ C), are covalently adhered via remarkably strong B– B, B– C, and C– C bonds, adding to its impressive mechanical rigidness and thermal security.

The presence of these polyhedral units and interstitial chains presents architectural anisotropy and inherent defects, which affect both the mechanical behavior and digital properties of the product.

Unlike less complex ceramics such as alumina or silicon carbide, boron carbide’s atomic style permits considerable configurational adaptability, allowing defect development and fee circulation that affect its performance under tension and irradiation.

1.2 Physical and Digital Features Emerging from Atomic Bonding

The covalent bonding network in boron carbide causes among the highest possible recognized solidity values amongst synthetic products– 2nd only to ruby and cubic boron nitride– typically ranging from 30 to 38 Grade point average on the Vickers hardness range.

Its thickness is incredibly low (~ 2.52 g/cm ³), making it around 30% lighter than alumina and nearly 70% lighter than steel, a critical benefit in weight-sensitive applications such as personal armor and aerospace parts.

Boron carbide shows outstanding chemical inertness, resisting strike by a lot of acids and antacids at space temperature, although it can oxidize over 450 ° C in air, forming boric oxide (B ₂ O ₃) and carbon dioxide, which might endanger architectural stability in high-temperature oxidative environments.

It has a vast bandgap (~ 2.1 eV), categorizing it as a semiconductor with possible applications in high-temperature electronics and radiation detectors.

Additionally, its high Seebeck coefficient and reduced thermal conductivity make it a prospect for thermoelectric power conversion, specifically in severe atmospheres where traditional materials fall short.

(Boron Carbide Ceramic)

The product likewise demonstrates outstanding neutron absorption because of the high neutron capture cross-section of the ¹⁰ B isotope (about 3837 barns for thermal neutrons), rendering it important in nuclear reactor control poles, securing, and invested gas storage systems.

2. Synthesis, Handling, and Obstacles in Densification

2.1 Industrial Manufacturing and Powder Manufacture Strategies

Boron carbide is mostly created with high-temperature carbothermal reduction of boric acid (H THREE BO FOUR) or boron oxide (B TWO O TWO) with carbon resources such as oil coke or charcoal in electric arc heating systems operating above 2000 ° C.

The reaction continues as: 2B ₂ O TWO + 7C → B FOUR C + 6CO, producing crude, angular powders that call for extensive milling to attain submicron fragment sizes suitable for ceramic handling.

Alternate synthesis paths consist of self-propagating high-temperature synthesis (SHS), laser-induced chemical vapor deposition (CVD), and plasma-assisted methods, which offer better control over stoichiometry and fragment morphology however are much less scalable for industrial usage.

Due to its extreme solidity, grinding boron carbide right into fine powders is energy-intensive and susceptible to contamination from grating media, necessitating using boron carbide-lined mills or polymeric grinding aids to preserve purity.

The resulting powders have to be carefully categorized and deagglomerated to ensure consistent packing and reliable sintering.

2.2 Sintering Limitations and Advanced Consolidation Methods

A major difficulty in boron carbide ceramic fabrication is its covalent bonding nature and low self-diffusion coefficient, which seriously limit densification throughout traditional pressureless sintering.

Also at temperatures coming close to 2200 ° C, pressureless sintering usually produces porcelains with 80– 90% of academic thickness, leaving recurring porosity that breaks down mechanical strength and ballistic performance.

To overcome this, advanced densification techniques such as warm pressing (HP) and hot isostatic pressing (HIP) are employed.

Hot pushing applies uniaxial pressure (generally 30– 50 MPa) at temperatures in between 2100 ° C and 2300 ° C, promoting particle rearrangement and plastic contortion, enabling thickness exceeding 95%.

HIP additionally enhances densification by applying isostatic gas pressure (100– 200 MPa) after encapsulation, removing shut pores and achieving near-full thickness with boosted fracture strength.

Ingredients such as carbon, silicon, or shift steel borides (e.g., TiB ₂, CrB ₂) are in some cases presented in tiny amounts to enhance sinterability and prevent grain development, though they may slightly reduce solidity or neutron absorption performance.

Regardless of these developments, grain border weak point and intrinsic brittleness remain relentless challenges, especially under vibrant filling problems.

3. Mechanical Habits and Performance Under Extreme Loading Conditions

3.1 Ballistic Resistance and Failure Devices

Boron carbide is extensively recognized as a premier material for light-weight ballistic defense in body armor, vehicle plating, and aircraft securing.

Its high firmness enables it to efficiently erode and warp incoming projectiles such as armor-piercing bullets and fragments, dissipating kinetic energy via mechanisms consisting of crack, microcracking, and localized phase transformation.

However, boron carbide shows a sensation called “amorphization under shock,” where, under high-velocity impact (generally > 1.8 km/s), the crystalline structure falls down into a disordered, amorphous stage that lacks load-bearing ability, causing tragic failure.

This pressure-induced amorphization, observed via in-situ X-ray diffraction and TEM research studies, is credited to the break down of icosahedral units and C-B-C chains under extreme shear stress.

Efforts to mitigate this include grain improvement, composite layout (e.g., B FOUR C-SiC), and surface coating with ductile steels to postpone split propagation and contain fragmentation.

3.2 Use Resistance and Industrial Applications

Past protection, boron carbide’s abrasion resistance makes it optimal for industrial applications including severe wear, such as sandblasting nozzles, water jet reducing suggestions, and grinding media.

Its solidity dramatically surpasses that of tungsten carbide and alumina, leading to extended service life and lowered upkeep prices in high-throughput production atmospheres.

Parts made from boron carbide can run under high-pressure abrasive circulations without quick destruction, although care has to be required to prevent thermal shock and tensile stresses throughout procedure.

Its usage in nuclear environments also encompasses wear-resistant parts in fuel handling systems, where mechanical resilience and neutron absorption are both needed.

4. Strategic Applications in Nuclear, Aerospace, and Emerging Technologies

4.1 Neutron Absorption and Radiation Protecting Systems

One of one of the most vital non-military applications of boron carbide is in atomic energy, where it works as a neutron-absorbing product in control poles, shutdown pellets, and radiation securing frameworks.

Due to the high abundance of the ¹⁰ B isotope (naturally ~ 20%, but can be enriched to > 90%), boron carbide successfully captures thermal neutrons through the ¹⁰ B(n, α)⁷ Li response, creating alpha fragments and lithium ions that are quickly contained within the product.

This reaction is non-radioactive and produces marginal long-lived byproducts, making boron carbide more secure and extra steady than options like cadmium or hafnium.

It is utilized in pressurized water reactors (PWRs), boiling water activators (BWRs), and study activators, often in the type of sintered pellets, clad tubes, or composite panels.

Its stability under neutron irradiation and ability to keep fission items boost activator safety and operational durability.

4.2 Aerospace, Thermoelectrics, and Future Material Frontiers

In aerospace, boron carbide is being checked out for use in hypersonic vehicle leading edges, where its high melting point (~ 2450 ° C), low thickness, and thermal shock resistance offer advantages over metal alloys.

Its potential in thermoelectric devices comes from its high Seebeck coefficient and reduced thermal conductivity, making it possible for straight conversion of waste warmth into electrical energy in severe environments such as deep-space probes or nuclear-powered systems.

Research is likewise underway to create boron carbide-based compounds with carbon nanotubes or graphene to improve toughness and electric conductivity for multifunctional structural electronic devices.

In addition, its semiconductor residential or commercial properties are being leveraged in radiation-hardened sensing units and detectors for area and nuclear applications.

In recap, boron carbide porcelains stand for a keystone product at the intersection of severe mechanical efficiency, nuclear engineering, and progressed production.

Its special mix of ultra-high hardness, low thickness, and neutron absorption capacity makes it irreplaceable in defense and nuclear modern technologies, while continuous study remains to increase its utility into aerospace, energy conversion, and next-generation compounds.

As refining techniques enhance and new composite styles arise, boron carbide will certainly remain at the center of products advancement for the most demanding technical difficulties.

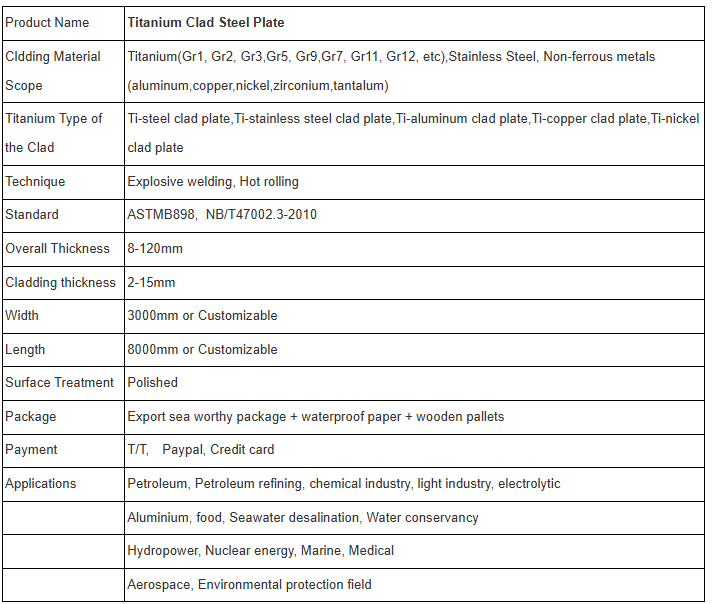

5. Provider

Advanced Ceramics founded on October 17, 2012, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products. Our products includes but not limited to Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, etc. If you are interested, please feel free to contact us.(nanotrun@yahoo.com)

Tags: Boron Carbide, Boron Ceramic, Boron Carbide Ceramic

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us