Every component in a train system should work well. This maintains the system secure and effective. Railway spreading parts are extremely vital. They supply assistance, attach points, and conduct signals. Their top quality affects just how steady the railway network is. When you acquire these components for South Africa, South America, or Russia, you should discover excellent manufacturers. To be effective, you need to understand the local technical guidelines. Below are 5 crucial high quality standards you must always comply with.

1. Product Structure & Mechanical Properties: The Structure of High quality

The performance of actors iron depends upon its details chemical make-up and casting process, and have to meet the international or local requirements of the target market. A trustworthy train casting components supplier will certainly supply complete product traceability.

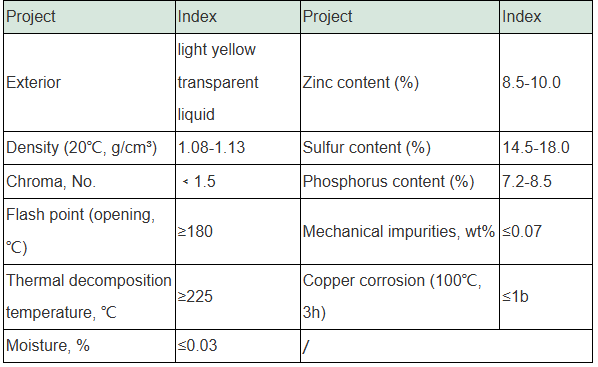

1.1 Composition Criteria: Have to comply with criteria such as International Standards (ISO), European Criteria (EN), Russian GOST standards, or those commonly utilized in South America like IRAM (Argentina) and ABNT NBR (Brazil). The content of hazardous aspects like phosphorus and sulfur need to be purely controlled.

1.2 Mechanical Qualities: Focus on tensile toughness, return stamina, firmness, and prolongation. For pliable iron, refer to criteria such as ISO 1083, EN 1563, or GOST 28394. Procurement should call for distributors to offer material certificates and mechanical examination reports that adhere to the target audience’s needs.

(Railway Cast Iron Gearbox)

2. Dimensional Accuracy & Tolerance Control: Ensuring a “Perfect Fit”

Train jobs worldwide have rigorous demands for dimensional interchangeability; any kind of variance can affect system combination. Accuracy is a mark of premium train casting makers.

2.1 Vital Measurements: All interface dimensions and installing opening positions for all railway casting components need to be 100% inspected.

2.2 Resistance Requirements: Should abide by internationally recognized criteria like ISO 2768, or certain tolerance needs clearly agreed upon with the customer. For the Russian and CIS markets, unique attention should be paid to abiding by appropriate resistance specifications in GOST 30893.

3. Limits on Casting Flaws: Removing Internal Hidden Dangers

The acceptance requirements for casting flaws have to be clearly defined in contracts and based on globally or regionally recognized specs. Leading train casting parts producer operations employ rigorous non-destructive screening.

3.1 Surface Flaws: Specifications like ISO 8062 can be referenced for assessing spreading surface area quality. Splits, cool shuts, and other defects impacting serviceability are not permitted.

3.2 Inner Issues: For vital load-bearing train casting components, non-destructive testing (e.g., ultrasonic, radiographic) should be carried out according to standards like ISO 4990, EN 12680, or the GOST R 55724 collection, with clear acceptance levels for defects.

4. Metallographic Framework & Internal Quality

The tiny structure of the material is the key basis for evaluating whether its inner quality satisfies the standard. This is a crucial check for any type of specialist railway spreading components supplier.

4.1 Ductile Iron: The evaluation of nodularization price must comply with criteria such as ISO 945-1 or GOST 3443 to guarantee its mechanical residential properties meet the demands for use under complicated working conditions.

4.2 Graphite Morphology & Matrix Framework: The metallographic assessment record is a vital document for verifying the stability of the manufacturing procedure and must follow the pertinent global or local standards.

(Railway Cast Iron Gearbox)

5. Anti-Corrosion Treatment & Surface Area Top Quality: Withstanding Harsh Environments

Given South Africa’s seaside high salinity, South America’s exotic rainforest moisture, and Russia’s severe cold and de-icing salts, anti-corrosion treatment for railway spreading components is vital.

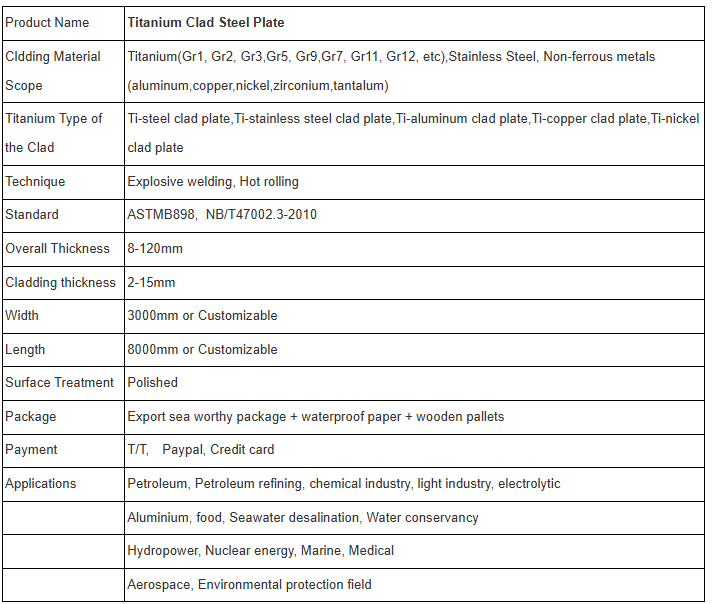

5.1 Treatment Processes: Specify the sort of anti-corrosion process, such as hot-dip galvanizing (ISO 1461), epoxy finishing, etc, and specify essential signs like coating density, bond ( e.g., ISO 2409), and salt spray resistance ( e.g., ISO 9227).

5.2 Regional Criteria: Must take notice of specific requirements of the target market, such as Russia’s GOST 9.307 anti-corrosion system accreditation, or South Africa’s SANS (South African National Standard) requirements. An international railway spreading manufacturers will certainly know with these varied demands.

Luoyang Fonyo Heavy Industries Co., Ltd. is a leading manufacturer of heavy industrial castings and components, focusing on providing top notch steel castings, including carbon steel, high manganese steel, alloy steel, and heat-resistant steel spreadings. With a comprehensive solution design integrating layout, casting, machining, and solution, Fonyo guarantees that each item meets extensive high quality and efficiency standards to please the demanding needs of numerous hefty markets.

If you are looking for a trusted supplier of Driving Rail Power, Luoyang Fonyo Heavy Industries Co., Ltd. is your ideal choice. Visit Fonyo’s official website (www.railwaypart.com) for more product information and technical support!

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us